Plastic Mould Process | Plastic Moulding Services | Plastic Mould Equipment Design Manufacturers

It generally experiences injection Moulding in various types, but the most popular technique is forcing a plastic liquid into a metal mould. The Moulding is made through the use of molten plastic that cools while it is inside the mould.

Plastic Mould are used to lessen down the prices related to various manufacturing procedures. This technology is favored because of the quick turnaround time in the procedure. A variant called reaction injection Moulding is additionally used for fiberglass, epoxy and polymer plastic. Here are ideas on gear design and the services, processes applied in the manufacture of these products.

Plastic Moulding Services

Plastic Moulding services result from rotational Moulding, blow Moulding, thermoforming and compression Moulding. Other services include mould prototyping, insert Moulding, micro-Moulding, two shot injection Moulding, machining and stamping that is hot. These services have features which make them distinct from one another.

Machining, for instance, is that stage where the forms are removed through turning, grinding or drilling. Micro-Moulding is understood to use mini and particular Moulding machines in order to create small parts out of the procedure. The parts produced out of these services are typically less than two grams in weight. In a two-shot injection, a plastic product is made from two sets of raw materials through the use of only one operation.

Plastic Moulding Procedures

Plastic Mould cannot be completed without experiencing some procedures. First on the list is the development of a three-dimensional or 3D CAD model. The making of a computer model is that point when a maker may ask a consumer for prototypes and concepts to see if they are good enough for the production of plastics. During the consultation period, production procedures may also be contemplated. Production rate, number of parts, kind of cost, materials and precision are used in the choice of the manufacturing process.

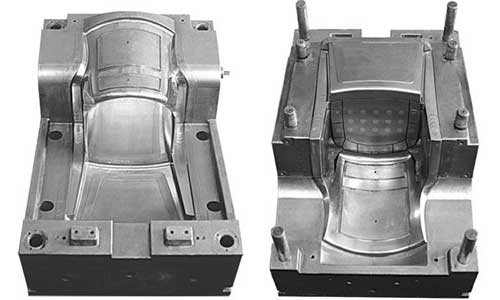

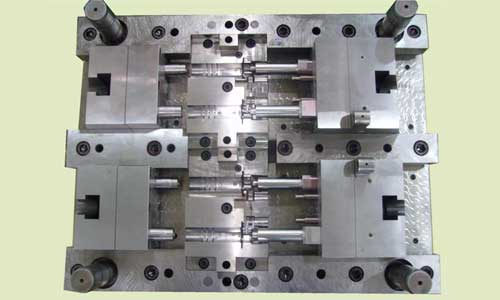

Plastic Mold Equipment Design

This important feature in production Plastic Mould is the fabrication of machinery to create the output. Barrels, linings, part, and feeders are also created out of the gear design. Along the procedure, particular types of equipment for different plastic mold services are formed. Machines for thermoplastic injection, blow Moulding and injection Moulding are a couple of examples of plastic mould equipment designs. The basic outcomes from these machines contain insulated runners as well as encapsulating, CAM, stack and insert Mould.

Construction Machinery

- Concrete Mixer

- Concrete Mixer with cast iron drum Type

- Concrete Mixer with Mechanical Hopper

- Concrete Mixer With Hydraulic Hopper

- Concrete Mixer With Lift

- Concrete Mixer Four Pole Lift Mobile Type

- Concrete Mixer Machine with Hopper and Lift

- Concrete Mixer Machine With Hydraulic Hopper & Lift

- Accurate Weight Batcher

- Half bag Concrete Mixer

- Slab Trolley

- Portable Concrete Mixer

- Monkey Hoist Or Mini Crane

Concerete Products Machinery

- Interlock Designer Tiles Making Table Vibrator

- Plastic/pvc Moulds for Interlock Paver & Bricks

- Interlock Tile Press

- Concrete Block Making Machine

- Semi Automatic Flyash Bricks Machine

- Fly Ash Brick Making Plant

- Concrete Block Making Machine Manual Type

Paver Block Making Machine

- Reflective Paver & Tiles Making Vibro Table

- Tile Mixer (Pan Mixer for Paver Block Top Layer)

- Interlock Tile Press

Table

Mixer Machine

Crane

Concrete Machine

Wood Machine

Brick Machine

Plastic Mould and Paver Block

- Section Design Plastic Moulds

- Zigzag

- Jumbo Colorado

- Chatura

- Plastic Mould 12x12

- Plastic Mould Cosmic

- 9x4x3 Plastic Mould Brick Design

- Colored Interlock Pavers Ready

- Plastic Moulds